DTF transfer, or direct-to-film printing, is an exciting breakthrough that is reshaping the landscape of custom apparel. This innovative method allows designers to create vibrant, detailed graphics that adhere seamlessly to a variety of fabrics, making it a go-to choice for t-shirt printing and personalized clothing. In this guide, we will delve deep into the art of DTF printing, exploring essential concepts such as sizing designs appropriately and selecting the right DTF print materials to achieve stunning results. With its unique ability to produce intricate patterns with remarkable color fidelity, DTF transfer is fast becoming a favorite among both hobbyists and businesses venturing into custom garment creation. By mastering this technique, you can unlock limitless possibilities for creating tailor-made designs that truly stand out in the competitive world of custom apparel.

The DTF transfer process, or direct-to-film process, has garnered attention for its ability to transform the custom clothing market. Utilizing advanced direct-to-film printing techniques, artists and entrepreneurs can achieve high-quality prints that bring their creative visions to life. As we explore the nuances of this printing method, we’ll cover everything from understanding sizing designs to choosing the best materials for your projects. The versatility of DTF printing caters to a wide range of fabric types, which is essential for those looking to innovate in custom apparel. By keeping abreast of the latest DTF printing guides and trends, you can enhance your skills and create eye-catching products that resonate with customers.

Exploring Direct-to-Film Printing

Direct-to-Film (DTF) printing is quickly emerging as a preferred technique in the custom apparel space. This innovative method creates stunning, high-resolution prints that can be applied easily to a variety of fabrics, including cotton, polyester, and their blends. Compared to traditional methods such as screen printing, DTF offers a much broader range of design possibilities while maintaining vibrant colors and fine details. The flexibility of DTF printing enables both hobbyists and businesses to expand their creative horizons, paving the way for personalized garments that resonate with individual customer taste.

Moreover, DTF printing appeals to startups and small businesses due to its relatively low investment in equipment and materials. A standard DTF printer can handle a diverse range of designs, from simple logos to intricate artwork, which makes it particularly advantageous for those just entering the market. This versatility ensures that custom apparel businesses can offer a wide variety of items, leading to greater customer satisfaction and improved sales potential. As the demand for customized clothing continues to grow, understanding the implications of DTF printing becomes paramount for success.

The Importance of Sizing for DTF Transfers

Sizing is arguably one of the most crucial aspects of executing a successful DTF transfer. The dimensions of your design must align with the size of the garment to maintain visual balance and aesthetic appeal. For instance, oversized prints on small shirts can lead to a disjointed look that detracts from the overall design. Conversely, too-small designs on large garments may get lost, negatively affecting the perceived quality of the apparel. Thus, mastering the art of sizing is essential for creating impactful custom apparel that stands out.

A strategic approach to sizing involves not just understanding general guidelines—like recommended dimensions for small, medium, and large designs—but also factors like garment style, fabric choice, and even the intended audience. For example, children’s clothing will require smaller designs, while t-shirts aimed at adult consumers may accommodate larger visuals. Similarly, varying fabric types can affect design appearance, thus making it vital to consider these elements when sizing your DTF transfers.

Recommended Materials for DTF Printing

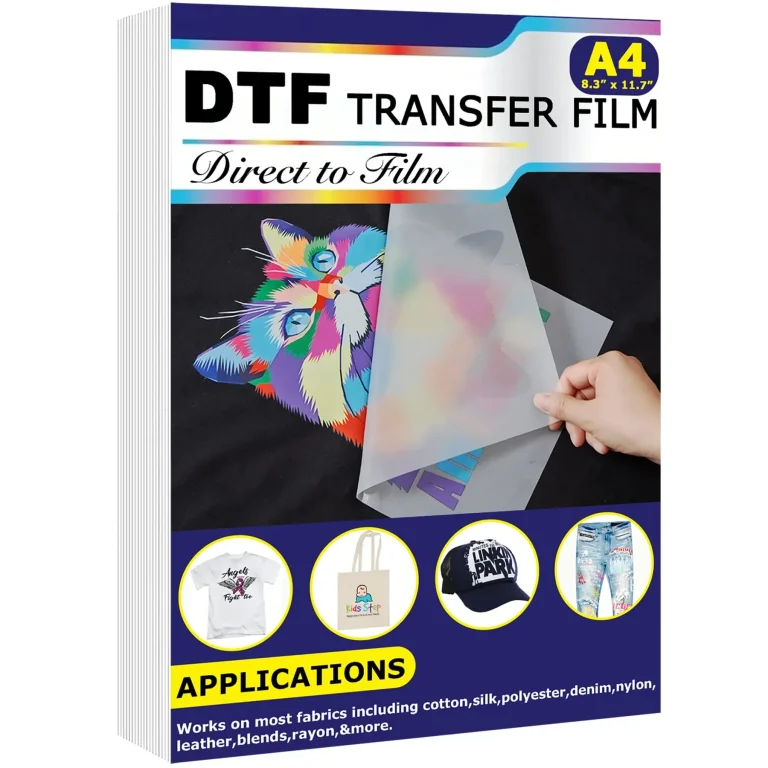

To achieve the best results with DTF printing, the selection of materials is fundamental. The primary requirement is a high-quality DTF printer that is specifically designed to use specialized inks. This step is crucial because the ink’s formulation ensures adherence to the transfer film and, ultimately, the fabric. Alongside a reliable printer, you will need transfer film, which is engineered for DTF applications to guarantee thorough and efficient transfer without compromising design quality.

In addition to the printer and film, obtaining the right adhesive powder is also vital. This powder bonds the ink from the film to the fabric during the heat-pressing process, ensuring a durable, long-lasting design. It is critical to source high-quality supplies to avoid printing mishaps and to enhance the durability of your final product. Investing in premium materials will result in stunning, professional-quality custom apparel that meets consumer demands and expectations.

Mastering the DTF Transfer Process

Understanding the DTF transfer process is essential for beginners seeking to create stunning custom designs. The process begins with designing your artwork, which should adhere to the size guidelines specified for the garment. Once the design is finalized, the next key step involves printing it onto the specialized DTF transfer film using the appropriate settings for optimal output. It’s imperative to ensure that the printer settings match the specifications of your DTF inks and film to achieve the best color integrity and detail.

After printing, the adhesive powder must be applied to the wet ink. This step is pivotal and should be done carefully to cover the entire printed image, ensuring an optimal bond when cured. Once the adhesive is in place, curing the ink is the next step, which can be executed through conveyor drying or by using a heat source. Finally, the most gratifying moment comes when the heat press is applied, changing the design from film to fabric and creating an eye-catching custom piece!

DIY Tips for Successful DTF Printing

As you embark on your DTF printing journey, several practical tips can enhance your experience and improve your outcomes. Firstly, testing various fabric types is essential before committing to large projects. Each fabric reacts differently to DTF transfers, so identifying the materials that work best with your designs can save time and reduce waste. It’s advisable to keep samples of your prints on different fabrics, helping you assess the durability and color fidelity of your designs.

Additionally, always remember to keep the size and placement of your designs in mind. Creating mock-ups or samples of your apparel can help visualize how the final product will look. Industry trends are ever-evolving, so staying informed and continuously learning about new techniques in DTF printing will ensure your skills remain relevant, allowing you to produce customized apparel that meets modern standards and client expectations.

The Future of DTF Printing in Custom Apparel

The future of DTF printing in the custom apparel market looks exceptionally promising. As technology continues to advance, the accessibility of quality DTF printing equipment is also increasing, making it an attractive option for aspiring entrepreneurs and established businesses alike. The rise of consumer demand for personalized clothing means that DTF printing will likely become even more mainstream, providing endless opportunities for innovation and creativity in design.

Moreover, advancements in ink formulation and transfer film technology are expected to improve print quality, durability, and overall customer satisfaction. These enhancements will provide custom apparel producers with the tools they need to push boundaries in their creative pursuits, further cementing DTF printing’s place as a vital technique in the apparel industry. Embracing these future developments will ensure that creators are well-equipped to meet evolving consumer desires and set trends rather than follow them.

Frequently Asked Questions

What is DTF transfer and how does it work?

DTF transfer, or direct-to-film printing, is a revolutionary printing technique used in customizing apparel. It involves printing designs on a specialized film, applying an adhesive, and heat pressing the film onto fabric. This versatile method can produce vibrant, detailed designs on various material types, making it a preferred choice for custom apparel.

What are the key materials required for DTF transfer printing?

To successfully execute DTF transfer printing, essential materials include a DTF printer, transfer film, adhesive powder, and a heat press. These elements work together to ensure optimal results, allowing for high-quality, vibrant designs on custom apparel.

How do I size my designs for DTF transfers effectively?

Sizing designs for DTF transfers is crucial for achieving visually appealing results. For children’s apparel, aim for 8-10 inches in width; for women’s medium and men’s small, 10-12 inches; and for larger sizes, designs can exceed 12 inches. Always match the design size proportionally to the garment size.

What types of fabrics are suitable for DTF printing?

DTF transfer printing is incredibly versatile and works well on a variety of fabrics, including cotton, polyester, and fabric blends. This allows for the customization of different garment types, making it suitable for a wide range of custom apparel projects.

Can I use DTF transfer for complex designs?

Absolutely! DTF transfer printing is ideal for complex designs as it allows for intricate details and excellent color fidelity. As you gain experience, you can experiment with more complex graphics to fully utilize the capabilities of DTF printing.

What are some tips for beginners in DTF transfer printing?

Beginners in DTF transfer printing should start with simple designs and practice sizing to perfect their technique. It’s essential to test different fabric types, monitor industry trends, and continually educate oneself to enhance skills and remain competitive in the custom apparel market.

| Key Points | Details |

|---|---|

| Understanding DTF Transfer | DTF printing involves printing designs onto a specialized film, followed by adhesive application and heat pressing to transfer to fabric. |

| Sizing for DTF Transfers | Small designs (8-10 inches), Medium designs (10-12 inches), Large designs (12+ inches) depending on garment size. |

| Materials and Equipment | DTF printer, transfer film, adhesive powder, and heat press are essential for effective printing. |

| The DTF Transfer Process | Steps: Design creation, printing on film, applying adhesive, curing the ink, and heat pressing the design. |

| Market Trends and DIY Tips | Growing demand for personalized products; start with simple designs and test different fabrics. |

Summary

DTF transfer is a transformative method for anyone looking to venture into the world of custom apparel printing. This efficient process allows users to produce high-quality, detailed designs that can easily be resized to fit various garment dimensions. Understanding the importance of sizing, choosing appropriate materials, and mastering the printing technique are crucial for success in this field. As the popularity of DTF printing continues to rise, beginners are empowered to unleash their creativity in crafting bespoke clothing that resonates in the competitive market. With the right approach and a willingness to learn, anyone can become proficient in DTF transfers and make their mark in the custom apparel industry.