DTF Gangsheet Builder is redefining efficiency in today’s competitive print market by simplifying how you plan multiple designs on a single sheet. Designed to streamline your DTF printing, it saves time, reduces waste, and speeds up production. For teams handling volume, it enables custom gang sheets by packing designs efficiently on one sheet. From setup to output, you’ll generate files that support a smooth production process and help you meet tight deadlines. In short, this tool strengthens the overall workflow from concept to transfer, delivering consistency and scale.

In practice, this technology serves as a layout engine that translates designs into a scalable production pathway. Think of it as a design-to-production platform that coordinates placement, spacing, color balance, and file readiness across multiple items. By automating layout decisions, teams can experiment with arrangements and lock in consistent outputs for batch printing. The emphasis is on template-driven processes, clear guidance, and outputs that printers can readily interpret, reducing setup time. As you evaluate tools, look for features that integrate smoothly with your existing systems and support reliable results at scale.

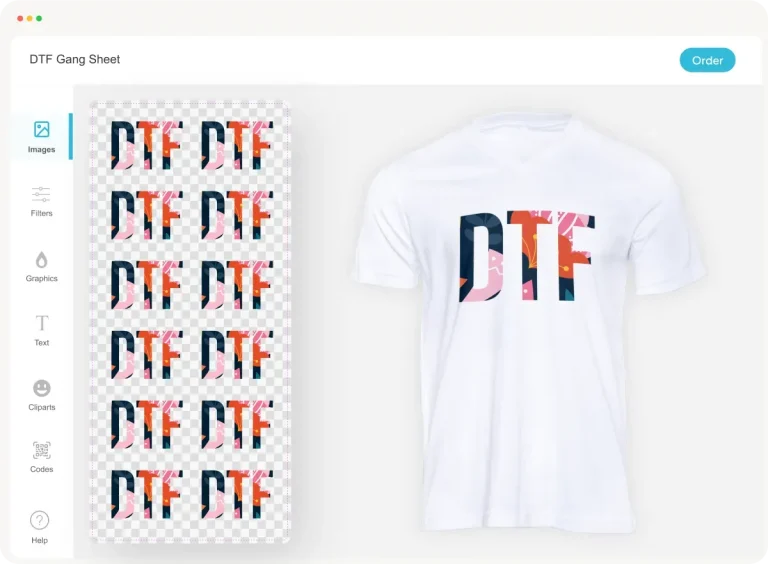

DTF Gangsheet Builder: A Game-Changer for DTF Printing

The DTF Gangsheet Builder is a centralized tool that makes planning, laying out, and exporting multiple designs onto a single sheet intuitive and fast. By weaving together design assets, spacing, and bleed settings, it fits neatly into a modern DTF printing workflow. It reduces manual rearrangements and helps teams move from concept to production-ready gang sheets with confidence.

As a core member of a DTF design software ecosystem, it aligns with standard file formats and color workflows. You can generate print-ready gang sheets that printers can handle with minimal preparation, minimizing setup time and misprints. This approach supports scalability, whether you’re producing a handful of designs or hundreds in a batch.

Designing Efficient Custom Gang Sheets for Faster Production

Designing efficient custom gang sheets is about maximizing fabric use while preserving design readability. The builder lets you arrange multi-design layouts on one sheet, ensuring safe margins and precise bleeds. For brands juggling many artworks, custom gang sheets reduce material waste and speed up the path from artwork to production.

Templates and constraints ensure consistency across runs, so output remains uniform even as new designs are added. This is part of the gang sheet workflow that translates creative ideas into a repeatable production process for DTF printing.

DTF Design Software Essentials for Accurate Color and Layout

DTF design software choices influence color fidelity, alignment, and print efficiency. By focusing on color management, vector-friendly exports, and bleed control, this category of tools helps preserve design intent from screen to fabric. The result is sharper transfers, more reliable color reproduction, and fewer surprises at the press.

Export options should be printer-ready, with formats such as PNG or TIFF and, where available, vector exports. Pairing robust design software with a gang sheet builder creates a smoother workflow and better compatibility with print production.

Streamlining the Gang Sheet Workflow with Drag-and-Drop Layout and Batch Processing

Streamlining the gang sheet workflow hinges on intuitive drag-and-drop layout and batch processing. A visual canvas lets you position designs quickly, while auto-snapping, alignment guides, and rotation rules keep everything tidy.

Batch processing enables importing multiple assets at once and letting the system optimize placement. The result is faster turnaround, fewer manual edits, and a more robust path from design to print-ready gang sheets.

Quality Control and Proofing: From Design to Print-Ready Gang Sheets

Quality control starts at the asset stage with resolution checks and color-proof validation. Build-in proofing helps catch issues before mass production, ensuring the final transfers match the on-screen design.

Color profiles and print tests are essential. Run quick proofs on sample garments, adjust color management, and refine margins and bleed settings. A disciplined QC process reduces misprints and material waste across large orders.

Best Practices for Scaling DTF Printing with Templates and Automation

Best practices for scaling DTF printing rely on templates, automation, and a clear documentation trail. By creating reusable sheet templates for common sizes and fabric types, studios can accelerate onboarding and maintain consistency.

As demand grows, automation widens throughput without sacrificing quality. The combination of templated layouts, automated color handling, and a well-defined gang sheet workflow positions your operation to take on larger campaigns with confidence.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve DTF printing workflows?

The DTF Gangsheet Builder is a dedicated DTF design software that automates the layout of multiple designs on a single sheet. It improves DTF printing by maximizing sheet space, reducing material waste, speeding up setup, and producing consistent print-ready gang sheets, with features like drag-and-drop layout, batch processing, and printer-ready exports.

How can I create custom gang sheets with the DTF Gangsheet Builder?

Define a custom sheet template (size, margins, bleed), import designs, then arrange via drag-and-drop. The builder optimizes placement to generate custom gang sheets that are ready for DTF printing, helping you maximize fabric usage and streamline production.

What features should I look for in DTF design software for gang sheets?

Look for drag-and-drop layout, batch processing, custom templates, color and bleed controls, export options compatible with your printer, design constraints, and thorough documentation. These features support a consistent gang sheet workflow and reliable print-ready gang sheets.

How does the gang sheet workflow benefit DTF printing?

The gang sheet workflow consolidates designs on fewer sheets, reduces setup time, and increases throughput. Templates and alignment guides ensure consistency across orders, while producing batch-ready files quickly for DTF printing.

Can I export print-ready gang sheets for different printers with the DTF Gangsheet Builder?

Yes. The tool supports printer-specific exports and color management so you can generate print-ready gang sheets in formats like PNG or TIFF that align with your DTF printer’s requirements and color profiles.

What best practices help avoid common pitfalls when creating gang sheets with the DTF Gangsheet Builder?

Use high-resolution assets, maintain a consistent color workflow, plan margins and bleeds, create reusable templates, proof on a sample garment, check for overlaps, and document settings to speed up onboarding and reduce reprints.

| Aspect | Key Points |

|---|---|

| Concept of a gang sheet | Definition: a large sheet that packs multiple designs to maximize fabric usage and minimize waste; benefits include reduced material costs, faster setup, and optimized print runs. DTF Gangsheet Builder automates layout decisions, spacing, bleed, and export-ready files. |

| Why a DTF Gangsheet Builder matters | Improves efficiency, consistency, accuracy, and speed by automating design placement, alignment guides, color management, and rapid export of print-ready files. |

| Core features | Drag-and-drop layout, batch processing, custom sheet templates, color and bleed controls, export options, design constraints, documentation. |

| Workflow: design to print-ready | Steps: Import designs → Define sheet parameters → Arrange layouts → Optimize color/output → Preview/adjust → Export. |

| Best practices | Use high-quality assets; consistent color workflows; plan margins/bleeds; reusable templates; proofing; document the process. |

| Use cases | Apparel brands with multi-design campaigns; customization boutiques; small studios scaling up. |

| Quality control & troubleshooting | Verify printer color profiles, avoid overlaps, maintain resolution, validate templates. |

| Advantages | Improved throughput, higher consistency, faster onboarding, better scalability. |

| Industry insights | Automation trend; cloud collaboration, batch color management, printer-specific optimization to future-proof operations. |

| Common pitfalls | Underestimating resolution, ignoring fabric variability, overcomplicating layouts, skipping proofs. |

Summary

DTF Gangsheet Builder is a transformative tool for modern print operations, streamlining design-to-production workflows, reducing waste, and accelerating output. By enabling templates, automated layouts, and precise color management, it helps solo designers, growing studios, and full-scale shops scale while maintaining quality. Implementing a dedicated DTF Gangsheet Builder can simplify onboarding, improve consistency across orders, and future-proof production as demand grows, turning concepts into production-ready gang sheets in minutes rather than hours. Ultimately, embracing this tool supports better planning, faster iterations, and more creative opportunities across your DTF printing business.