DTF transfer by size offers a practical lens into how artwork scales across garments and surfaces, turning a concept into measurable outcomes that printers can act on from day one. In this DTF sizing experiment, we test several transfer dimensions on diverse fabrics to observe how image scale affects color density and edge fidelity, revealing where small details survive or blur at larger formats. The results guide a DTF transfer test protocol that standardizes temperature, time, pressure, and curing conditions so size is the only variable shaping outcomes, helping teams quantify variance and minimize misinterpretation. This structured approach helps designers, printers, and shop owners calibrate expectations and optimize workflows for a broad product range across apparel, accessories, and home textiles, supporting scalability too. By documenting how different sizes perform, you build a reusable sizing matrix that improves consistency and customer satisfaction across substrates, enabling faster prototyping and more reliable production planning.

From an LSI perspective, Direct-to-Film sizing reveals how increasing dimensions influence print fidelity across fabrics. Using alternative terms such as scale-driven performance, dimensional print quality, and cross-substrate consistency helps communicate the concept to engineers, operators, and marketers without over-committing to a single jargon. This broadened framing can also address practical concerns like how heat press impact on DTF transfers varies with surface texture and fiber blend. By pairing descriptive terms with data from real tests, teams build a resilient, scalable workflow that supports consistent results regardless of size or substrate.

DTF Transfer by Size: Mapping Artwork to Real-World Applications

DTF transfer by size is a practical approach to understanding how artwork scales on different garments and surfaces. By testing multiple transfer sizes on a representative range of fabrics, designers and printers can predict how image resolution, color density, and edge quality behave as the design grows. This method turns a marketing phrase into actionable insight that informs substrate selection, artwork preparation, and production planning.

In practice, the goal is to translate the Direct-to-Film workflow into predictable outcomes. By standardizing temperature, time, pressure, and curing conditions, a DTF transfer by size study isolates size as the variable, enabling clear comparisons across cotton, cotton blends, and polyester fabrics.

DTF Sizing Experiment: Designing a Robust Size Matrix Across Fabrics

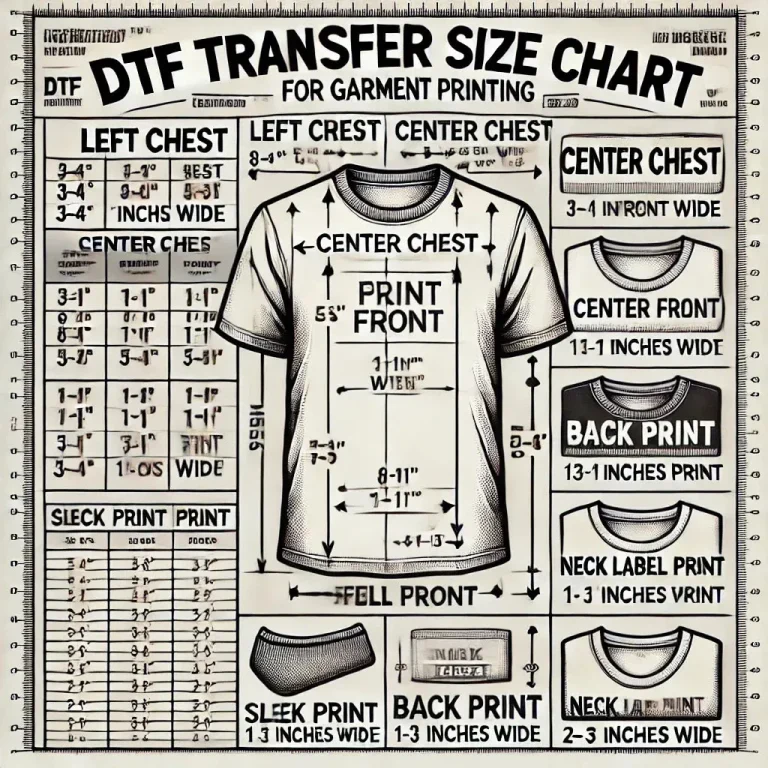

A DTF sizing experiment forms the backbone of size-aware printing. Start with a size matrix that includes small, medium, and large formats (for example, 2×3, 4×6, 6×8, and 8×10 inches) and apply them to multiple fabrics such as 100% cotton and cotton-poly blends. This setup reveals how each substrate responds to scaling in terms of ink coverage, dot gain, and wash durability.

Observations from the DTF sizing experiment guide practical decisions: which sizes deliver the best edge definition on a given fabric, where color density remains consistent, and how edge integrity can degrade nonlinearly as size increases. The resulting sizing matrix helps designers set expectations and printers plan production flow.

DTF Transfer Test: Evaluating Color Density, Edge Crispness, and Durability by Size

A DTF transfer test focuses on core performance metrics across sizes, including color density, edge crispness, gradient fidelity, and adhesion after washing. It compares how reliably a logo or artwork maintains saturation and sharp details when scaled from small to large formats.

Results from a DTF transfer test inform concrete actions, such as recommended minimum density for larger transfers, adjustments to pre-press or dwell time, and substrate-specific guidelines to preserve color accuracy and longevity across products.

DTF Printing Quality by Size: Substrate-Specific Considerations and Outcomes

DTF printing quality by size is heavily influenced by substrate properties, including fabric type, weave, and pretreatment. The same design may print with high color purity on cotton but show softer gradients on polyester blends, underscoring the need to tailor ink density and exposure per size and substrate.

By testing across fabrics and sizes, teams build a library of size-specific guidelines, enabling consistent outcomes when applying DTF transfers to different product lines. The insights support better artwork prep and production planning for reliable results.

Direct-to-Film Sizing: Strategies for Consistent Results Across Different Garments

Direct-to-Film sizing is about applying a standardized approach across variants such as shirts, sleeves, hats, and panels. Establish a baseline set of process controls—temperature, pressure, and dwell time—that remain constant across sizes while adjusting placement and design layout to preserve alignment.

With directed sizing strategies, shops can reuse findings from one product to another, reducing trial-and-error. A robust Direct-to-Film sizing plan helps ensure that color, detail, and durability align with customer expectations across the product spectrum.

Heat Press Impact on DTF Transfers: Temperature, Pressure, and Time Effects Across Scales

Heat press impact on DTF transfers is dramatic when you scale from small logos to large panels. Temperature, pressure, and dwell time interact with size to influence ink transfer, gloss, and edge fidelity. Larger formats may require adjusted energy input to achieve full saturation without scorching.

Operational tips emphasize stable heat sources, accurate temperature control, and consistent cooling. By monitoring platen temperature and using a calibrated thermometer, teams can preserve gradients and fine details across sizes, supporting reliable DTF printing quality by size.

Frequently Asked Questions

What is DTF transfer by size and why is it used in production planning?

DTF transfer by size is a structured approach to predict how artwork scales on different garments and surfaces. In a DTF sizing experiment, you test multiple transfer sizes on several fabrics while keeping temperature, time, pressure, and curing conditions constant to isolate size as the variable. This helps designers and printers set expectations and standardize the DTF workflow for real-world results.

What fabrics and sizes are typically included in a DTF sizing experiment?

A representative DTF sizing experiment uses a size matrix such as 2×3, 4×6, 6×8, and 8×10 inches printed on fabrics like 100% cotton, cotton blends, and polyester blends. By testing these combinations under identical heat press settings, you can compare color density, edge definition, and durability across sizes.

How is DTF printing quality by size evaluated across different substrates?

Evaluation focuses on color density and uniformity, edge definition, detail fidelity, texture, and durability across sizes and fabrics. Document results with photos and measurements to compare performance and refine the size-based guidelines for DTF printing quality by size.

How does heat press impact on DTF transfers change with size?

The heat press impact on DTF transfers is more pronounced at larger sizes due to pressure distribution and heat uniformity. Maintain stable platen temperature, consistent dwell time, and even compression; adjust pressure or time if needed to prevent edge blurring or under-inking.

What guidelines from Direct-to-Film sizing help choose substrates and optimize artwork at different sizes?

Direct-to-Film sizing findings show how cotton vs. polyester blends respond to size, suggesting fabric-specific density targets and pre-press adjustments. Use size-specific guidelines to select substrates, plan ink density, and preserve gradients and detail when scaling artwork.

What steps should a shop take to implement a robust DTF transfer by size workflow?

Define a size matrix and set one or two baseline heat/pressure/time settings; run controlled tests across fabrics; document outcomes with a simple lab log; design at the largest size first and scale down; reuse findings to build a practical sizing guide.

| Aspect | Key Points |

|---|---|

| Purpose | DTF transfer by size is a practical approach to predict how artwork scales on different garments and surfaces, enabling actionable guidance for designers, printers, and print shops. |

| Materials & setup |

|

| Experimental design |

|

| Size matrix |

|

| Fabric selection |

|

| Process consistency |

|

| What to look for |

|

| Interpreting results |

|

| Guidelines & tips |

|

| Pitfalls & troubleshooting |

|